MAINERO

Mainero for all your Grain Storage Solutions

MAINERO 2330 EXTRACTOR

With the 2330 grain pump model, you can work either in bags or cells and with a remarkable extraction performance. You can select within different qualities, as you can adjust hydraulically the extraction height.

SOME TECHNICAL FEATURES OF THE 2330:

Mechanic extraction system: Extraction is done through a mechanical system constituted by three augers, one principal at the center, and two lateral sweeping augers. We choose a mechanical system because it reaches high performance work -100 a 120 tn/h- using low power tractors (minimum 70 hp DIN), thereby, amortization, labor and fuel costs are significantly reduced.

Customizable to different bags sizes. To adapt to 5 to 10 ft diameter bags (1.52 a 3.04 m) the extraction width should be adjusted by the opening or closing of the lateral augers, even on the go. This adjustment is made through two manual commands.

Floating extraction set for an efficient sweeping. The extraction set works flat on the floor through a set of three floating brushes mounted on each lateral sweeper. At the same time, is linked to the chassis by a registrable spring system that absorbs ground unevenness and avoids the load of caked or crusted material without the need of adjustments on the go, enabling also, to proceed without damaging the bottom of the bag. All this characteristics determine that you can start and finish the bag sweeping, ending your tasks rapidly, without effort , and practically without the need of shoveling.

To set the extractor in transport position, all you need is fold the unloading auger, lift the extractor set (both from the tractors hydraulic distributor) and place a safety lock. The transport maximum width is 1.84 m (6.04 ft)

SAFETY CERTIFICATE

In order to increase the operational safety, and decrease accident risks and pollution, and also to simplify preservation and transportation of the unit, this equipment has all the elements necessary to conform to safety standard in agricultural machinery IRAM 8076-0. Each unit delivered has a sticker certifying that the product meets the standard.

MAINERO 2230 BAGGER

An option for every need, MAINERO has the most complete line of grain baggers.

The filling tunnel features the option of working with 9 ft diameter bags (2,74 m) and 60 or 75 m length (65.6 or 82 yd). Due to its “flattened” shape, facilitates the natural flux of material inside the bags, providing an evenly filling that makes the most of the storage capacity.

The stretching of the bag and therefore its storage capacity, is adjusted through a disc brake system, mounted over both wheels, and the braking force is graduated by an independent pump, manually operated.

To disengage the tractor, even during work (with a started bag) two side support feet are used.

For the assembly of the bags, It comes with a built-in retractable support inside the tunnel, which is in charge of lifting the bag by a manually operated winch.

The transport position is identical to the operating mode, reaching a maximum width of 3.3m (3.6 yd), Moreover, It doesn’t need additional elements to change from one position to the other, just operate the agricultural type hydraulic cylinder from the tractor.

There is an optional kit for the spear transport, consisting of two wheel brackets, a spear and a light set. In this mode, the equipment has a minimum width of 2,16 m (2.36 yd). For this purpose and to transport it easily by truck as well, the working spear is rebuttable.

In order to increase the operational safety, and decrease accident risks, the bagger meets the Agricultural equipment security standards IRAM 8076-0.

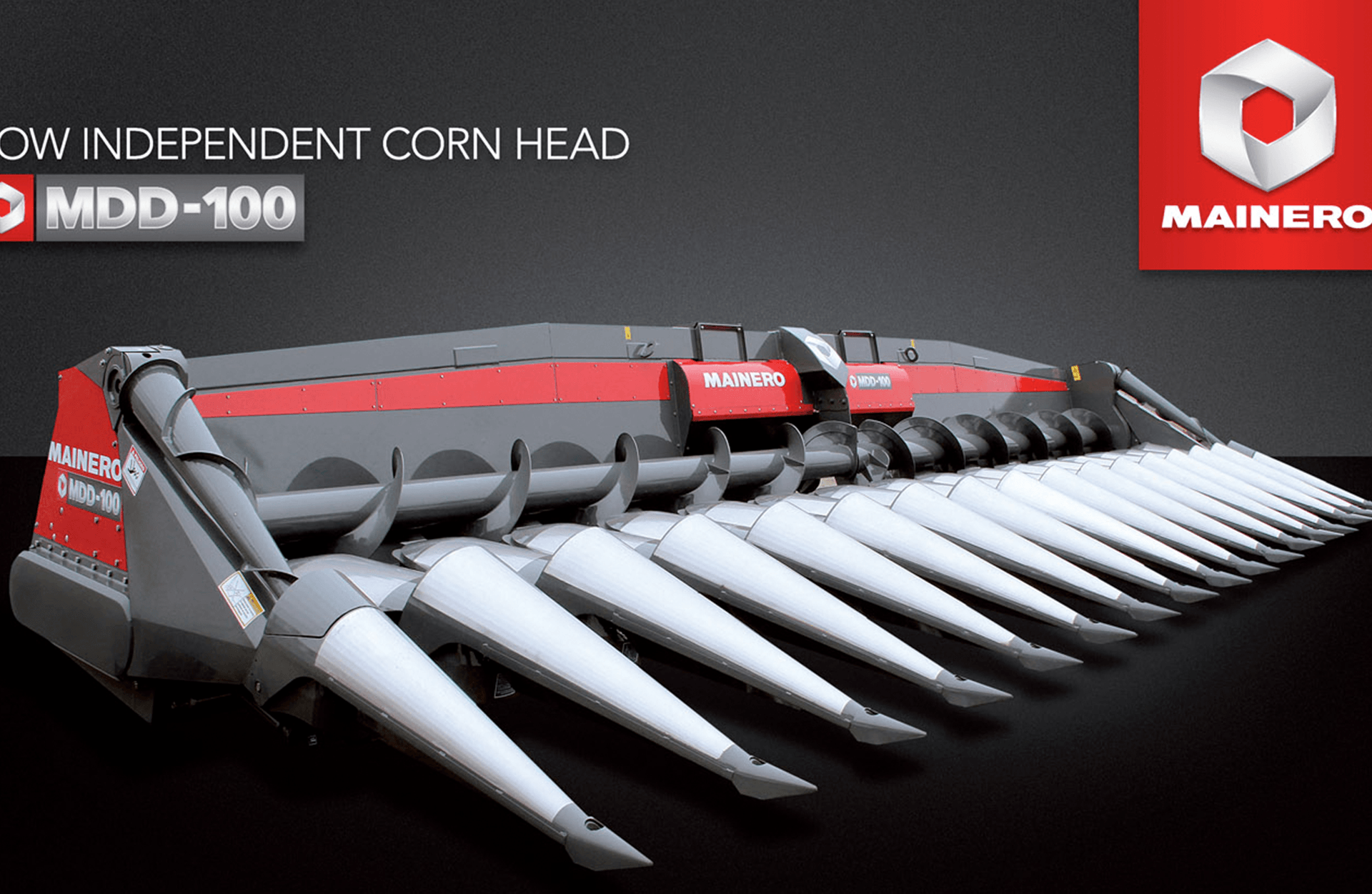

MAINERO MDD100 CORN FRONT

NEW MAINERO MDD-100 CORN HEADER, FOR MULTIPLE SPACING AND DIRECTION

There are many kinds of corn heads but they all require the head to match up with the row spacing planted and the operator must travel in the same direction it was planted.

The Mainero MDD-100 Row Independent corn head can harvest any and every row-spacing and in any direction without adjustments or modifications in a wide range of crop conditions.

Even in downed crops this corn head keep loss levels at a minimum and without ground speed restrictions. This new design allows stalks to enter the row-unit stripping area smoothly where they are misaligned.

The new, shorter snouts are mounted more rearward as compared to previous heads allowing the row unit gathering chains to work further ahead with a gentler action. The open-sided snout design allows the corn stalk to stay attached to the ground and then gently eased over rather than break off as with a conventional snout.

The new double-sprocket gathering chain tensor arm provides a wide V-shape that forms a broad entry channel for misaligned stalks allowing them to get to the stripping area without being shaken, thus avoiding the ear to drop.

It allows the farmer to plant corn at any row spacing and allows the custom harvesters to fit every row spacing and harvest in any direction with just one header.

Some technical features of the Grain Cart MAINERO 5361 are:

- Capacities of 36,000 liters.

- Diameter of the vertical auger tube: 550mm

- Diameter of the horizontal auger tube: 375 mm

- Discharge speed: 12.500 kg per minute

- Chassis monoblock, greatly increases the robustness of the unit.

- Innovative modular bottom to download and easy to clean.

- Robusts frontal and rear axles

- Cemented augers

- Roll tarp covering system

- Indicator of cereal entry gates opening at ground augers.

- Non skid stairs, internal and external of the hopper.

- Broad front viewers, for the observation of the cereal level inside the trailer.

- Discharge pipe articulation with self locking arm.

- Ready to place an electronic scale. Optional.

- Anti-slip rear folding ladder.

- Folding rear bumper and taillights.

- Electrostatic paint.

MAINERO 5361 CHASER BINS

The mainero self unloading grain carts, of 32 ton, offer an innovative design, robustness and excellent download speed. The mainero self-discharge hoppers are designed to meet the needs of producers, regarding capacity working speed and also adapted to the requirements of different markets.